"Wellish"U Series/J Type Energy Saving Servo Machine

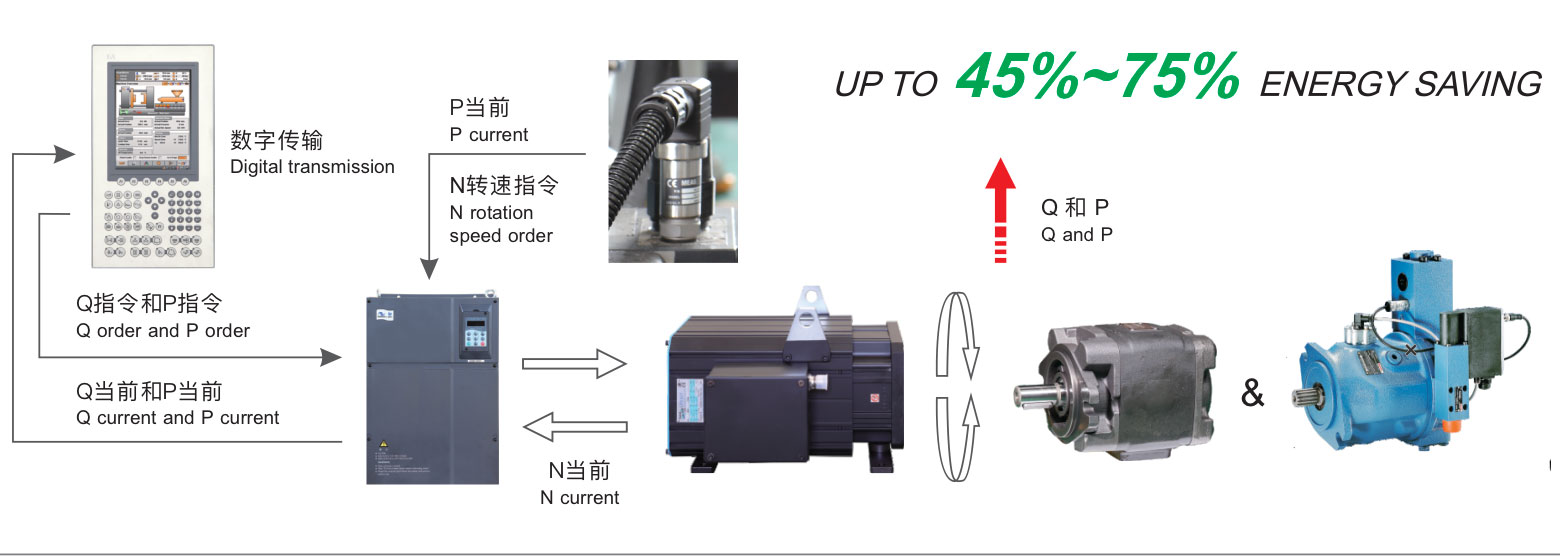

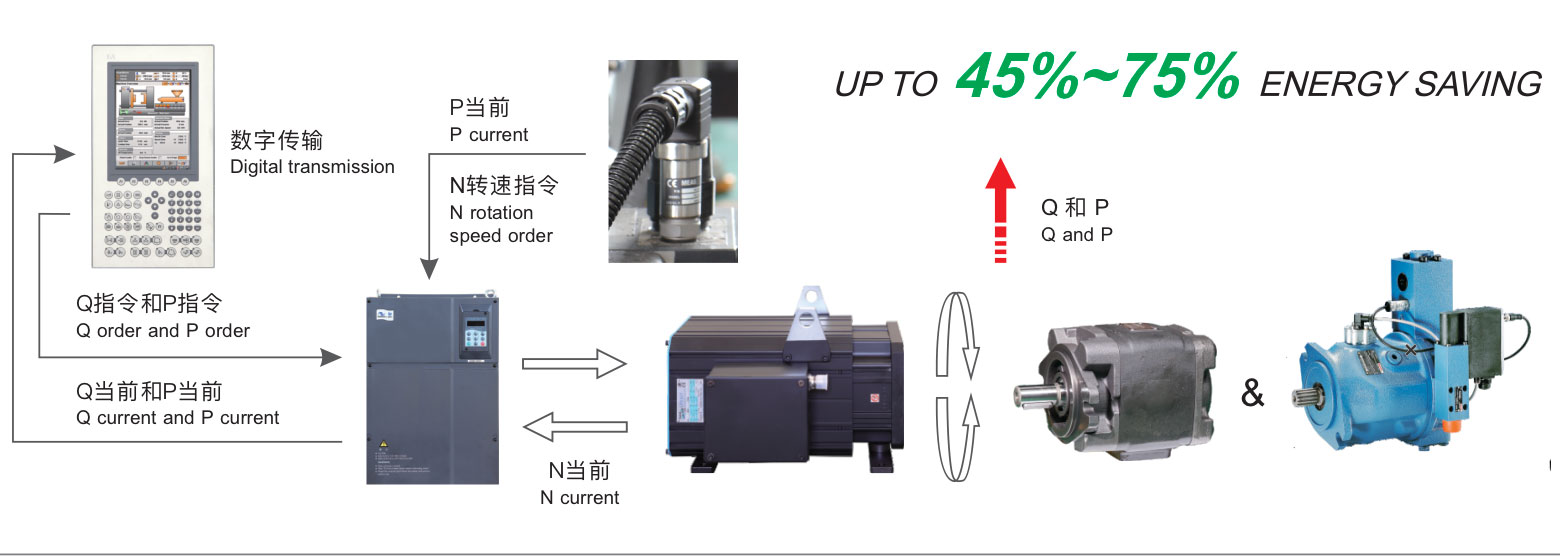

J Series system design high energy-saving injection molding machine has been listed in our National Torch Plan and we+re the earliest domestic company who is engaged in this project. Servo motor can dictate different machine action according to product workmanship requirement, it will input data into the controller and instruct each machine+s movement quickly based on different load demand. The linearity of servo driving system operational process keeps good tracking with technological instruction. Therefore, the system pressure and flow becomes a closed loop, which achieves scientific combination of high machine performance & high energy-saving (45%~75%). With this high-response system, the machine working efficiency can reach 98% or more.

Included in the NATIONAL Torch plan, Advocating energy-saving technolog

Obtained national first-level energy efficiency

Show High Precision

The accurate injection positioning, pressure, speed and pressure maintaining, to ensure the repeatability error of injection accuracy less than 0.3% to achieve precision molding.

Super Energy-Saving Features

Compared with standard injection machine, the energy saving rate can reach 45%-75% for the same plastic production

High Efficiency

Compared with standard machine, the total efficiency can increase by 10% and dragging capacity is can increase by 18%

High Response System

The system acceleration and deceleration performance is quite agile and force & speed regulation is very sensitive. The sampling processing speed can reach 100KHz and system quick start time can reach 0.05s.

Maintain Stability and Reliability

The pressure or speed is stable and switch of pressure maintaining is smooth and accurate.

Low Oil Temperature

Avoid high pressure unloading and low oil temperature situation during operation. Improve the operation performance, promote using efficiency and save a large quantity of cooling water.